Drilling and Milling with a Laser?

From wafer-thin glass to glass blocks over 100 mm thick, you can drill and mill in all thicknesses with our "cericut" laser-process. With the laser, you can now drill and mill even more efficiently and cleanly!

The "cericut" laser process has several advantages over traditional methods:

- There are no mechanical forces acting on the glass.

- The laser allows the highest precision and quality without pre- or post-processing of the cut edges.

- Hardly any heat is released, so no coolants are needed.

It is virtually a cold, dry process, and the laser-induced material atomization produces very little glass dust, which is simply extracted at the point of processing.

"cericut" means minimal production costs, no prior washing of the glass and no purchase of consumables, with maximum flexibility in shaping.

Drilling

Thanks to a patented process, any conceivable shape (including shapes previously thought impossible) can now be created in glass with the help of a cericom laser machine. This is because the laser offers the advantage that it is completely free in its movement and can drill into the glass without contact and without the coolant that would otherwise be required – with the highest accuracy.

The cut edge that results is only 100 micrometers wide, extremely precise and free of microcracks. Whether the glass is only 0.5 mm or 20 mm thick is irrelevant. Holes from 0.2 to 20 mm and more are no problem for our machines.

The cericom laser machines offer an essential advantage in production: the process is economical and time-saving, the machine works up to the highest quality standards, and the product is reproduceable at all times. For industrial use, these are elementary key factors for the profitability of such an investment.

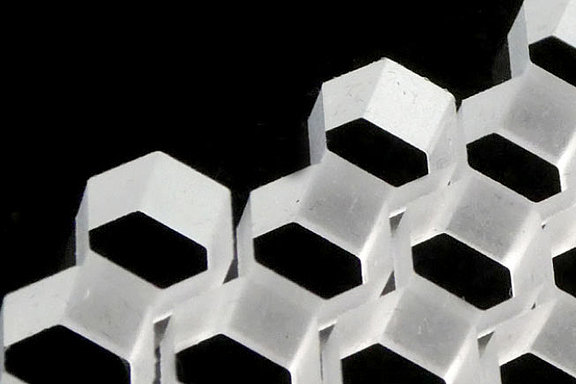

Milling

When milling glass using the patented cericom process, the laser beam is guided at high speed over the underside of the glass and the glass material is removed by vaporization or pulverization.

The high flexibility of the laser beam enables rapid movement of the laser focus in all directions. As a result, it is now possible to realize complex shapes with high precision and without undesirable subsurface damages to the glass.

Please feel free to send us an e-mail for further information to info@cericom.de or call us directly at +49 571 38 863 66.

![[Translate to English:] Fräsen und Bohren](https://www.cericom.de/fileadmin/_processed_/9/0/csm_header_bohren_1a390f57b6.jpg)