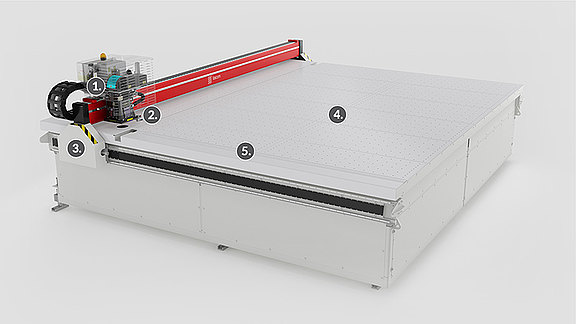

The L-matrix LDC removes transparent but conductive layers (e.g. low-E layers) from the glass at speeds of up to 360 mm²/s to create conductor structures of any width and shape for heating.

As an additional option, you receive powerful software for modelling the temperature curve for any glass size and shape - to ensure uniform heating, for example. Conversely, it is also possible to calculate different temperature values in different areas of the glass and thus partially intensify the heating power, e.g. for the parking area of car windscreen wipers.

Each laser module and the machine are guaranteed for 1 year with no limit on operating hours for the entire machine. The laser offers a coating removal speed of up to 8 m/s in a straight line and up to 360 mm²/s in the area. The decoating performance of the L-matrix LDC system is up to 15 x higher than the traditional acid etching process.

The laser enables a combination of high speed and precise separation joints - so-called "cutoffs". The width of the generated cutoffs can be varied from 35 µm to several millimetres.

A 0.5 mm wide cutoff provides up to 1 kV of isolation in dry air without breakdown. In a finished construction (e.g. laminated glass), the 0.05 mm wide cutoff can withstand up to 600 volts. This is achieved by the complete removal of the coating material by laser radiation and without damaging the glass.

This is achieved by the complete removal of the coating material by laser radiation and without damaging the glass.

The L-matrix LDC offers high productivity, flexibility and precision. In addition, labour requirements can be significantly reduced compared to conventional processes: Only one operator is required to run an entire line for the production of electrically heated glass.

A major advantage of the laser is the environmental compatibility and safety of the process - especially compared to the traditional acid etching method, which is harmful to the environment and personnel.

L-Heatware: Our software solution for heating simulation

In order to perfectly control the operation of the L-matrix LDC | Laser DeCoating tables, our engineers have developed software that makes it possible to calculate the heat output (in watts per unit area) even for glasses with complex shapes and to select an optimal arrangement of cutoffs and busbars. This eliminates the need to create prototypes, which in turn significantly reduces the costs for small series and individual orders.

Laser performance

| Basic performance | 130 mm²/s |

| After installation of a more powerful laser (optional) | 360 mm²/s |

| Scanner processing field | 180 ×180 mm |

* Values are given without regarding time of positioning

Serial production

| Glass marking | ext. option |

Operator’s safety

| Light barrier | ext. option |

| Safety fencing | ext. option |