You want to frost the surface of glass?

You would like to structure glass 3-dimensionally on the inside?

You want to drill glass into complex shapes without having to touch it?

Then you have come to the right website!

We offer trend-setting and optimal solutions for the structuring or ablating of glass coatings, and for the machine-readable and aesthetically sophisticated marking of glass. With the concentrated power of a laser beam, that is integrated in our machines, you can decorate and drill glass without having to touch it. We combine glass and light in unimagined ways and we can guarantee this through our many years of consistent further development.

Shape your future by investing in a cericom laser machine!

Discover new possibilities!

cericom - your specialist in glass laser processing technology.

We are delighted to welcome another new member to our rapidly growing R&D team: Tung Son Le

Position: Software Developer ...

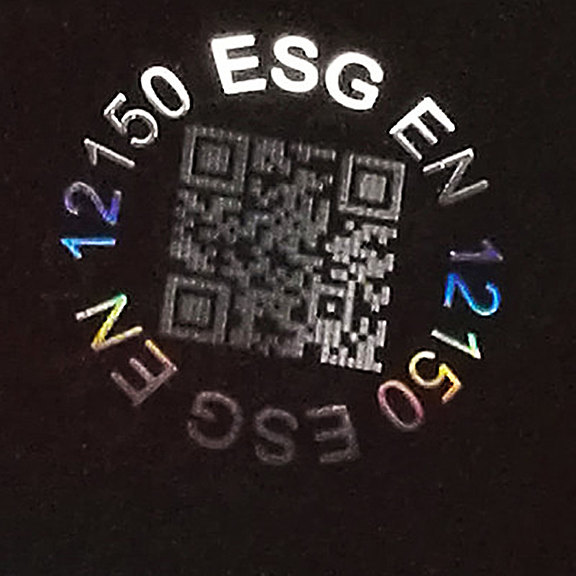

For marking, matting, surface engraving

For this application, mainly CO2 lasers are used on cericom machines. With this type of laser, you can process the surfaces of all flat glass products available on the market without restriction and structure many coatings.

The glass surface is frosted by the CO2 laser beam via a small amount of material removal and additional melting of the glass surface. Advantage: Laser-matted glass surfaces are less sensitive to fingerprints and dirt than glass surfaces that are roughened by sandblasting or etching.

In addition, the glass marking can also be used specifically to create slip-resistant glass surfaces. For this purpose, however, no additional material is applied to the surface, but only micropores are created with the laser beam that are subject to almost no wear.

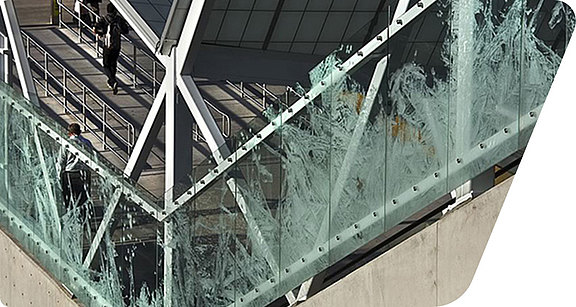

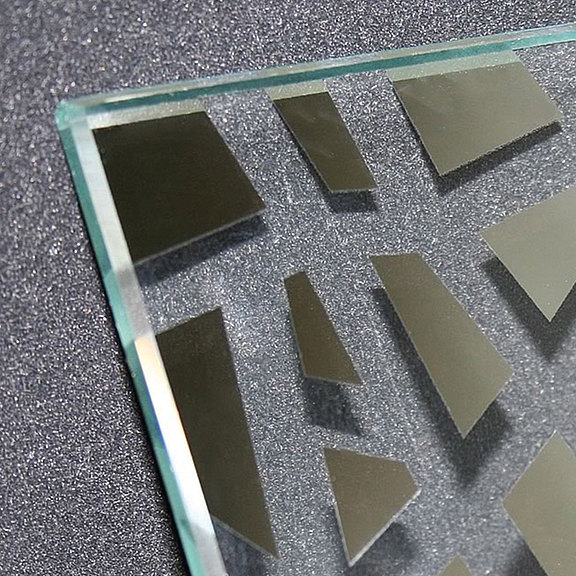

For decoating

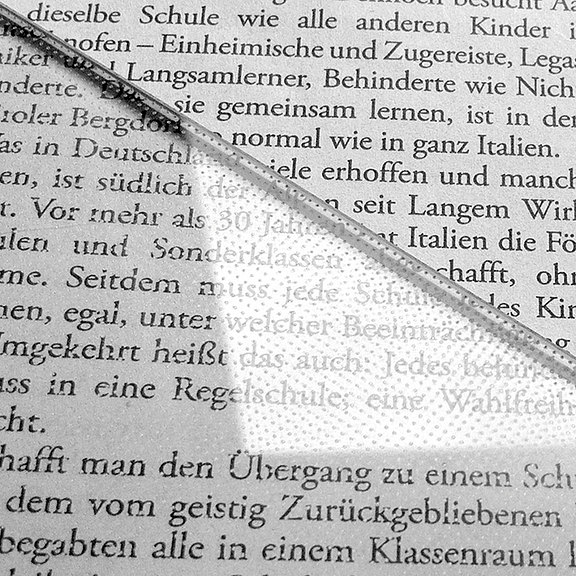

Clear coatings are removed with pulsed infrared lasers, matt coatings are removed with CO2 lasers. In addition, we offer other lasers as an alternative in order to achieve the best quality and productivity - depending on the type of coating. Depending on the laser process, coatings such as lacquers, mirror coatings, baked-on or not yet baked-on enamel, LowE coatings or even conductive coatings can be removed and structured in a targeted manner and with the highest resolution. The process developed by cericom for targeted laser ablation enables flexible and economical decoating or structuring of glass for changing designs and both large and small quantities.

Laser ablation can achieve significantly higher resolutions and contour sharpness than screen or digital printing. Sampling can also be carried out quickly and efficiently using laser decoating, as no intermediate steps are required. The glass exposed under the coating usually remains undamaged without any matting of the glass surface.

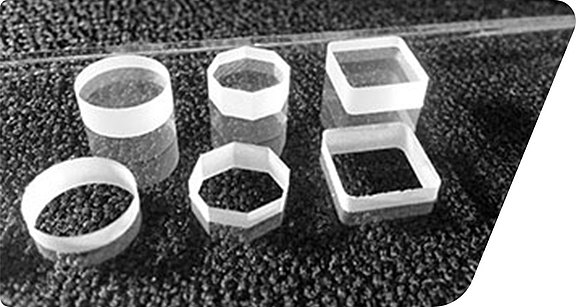

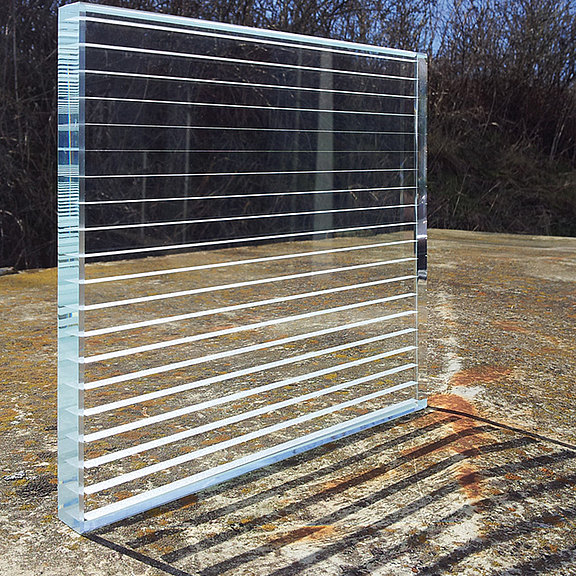

For internal engraving, milling & drilling

A particularly innovative highlight of cericom are laser machines for drilling, cutting and 3-dimensional structuring of glass surfaces.

For processing technical glass, the laser process offers clear qualitative and economic advantages - with high growth potential for our customers' industrial applications: Particular advantages of laser cutting are the free shaping, the completely force-free process without coolant as well as an outstanding final quality of the cut edge - this usually requires no further finishing. If desired, the edge of a cut or a hole can be provided with a chamfer or rounding directly in the process.

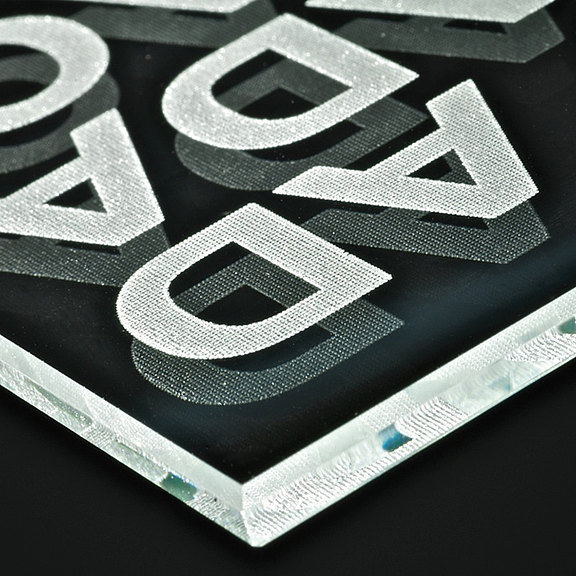

For internal glass engraving, solid-state lasers are used that work with visible laser radiation in the green wavelength range. Internal engraving always requires a clear, smooth and transparent glass surface so that the laser beam can penetrate unhindered - in order to specifically modify the glass structure there and thus create a laser engraving inside the glass.

Furthermore, laser engraving on the inside can often also be carried out on frosted glass: Since usually only one side of the glass is frosted or coated, the internal engraving can be done from the clear side of the glass in this case.

For internal engraving

Internal glass engraving is performed using solid-state lasers, which operate in various wavelength ranges depending on the requirements. Internal engraving always requires a clear, smooth and transparent glass surface so that the laser beam can penetrate unhindered - in order to specifically modify the glass structure there and thus create a laser engraving inside the glass.

Furthermore, laser engraving on the inside can often also be carried out on frosted glass: Since usually only one side of the glass is frosted or coated, the internal engraving can be done from the clear side of the glass in this case.

cericom laser

(Pages with a white background)

Our core business is the manufacture of machines for industrial laser processing of glass. Laser marking, laser frosting, laser decoating andlaser drilling

Direct links to the machines:

c-vertica

cericom crystal

(Pages with a black background)

In this separate division, we dedicate ourselves to more compact machines that can be used for stationary or "on-site" individual engraving, for example 3-D portraits. Here it's not just about the machine itself, but also about all-round service.

https://www.cericom-crystal.de/home

Direct links to the machines:

c-jet

c-professional