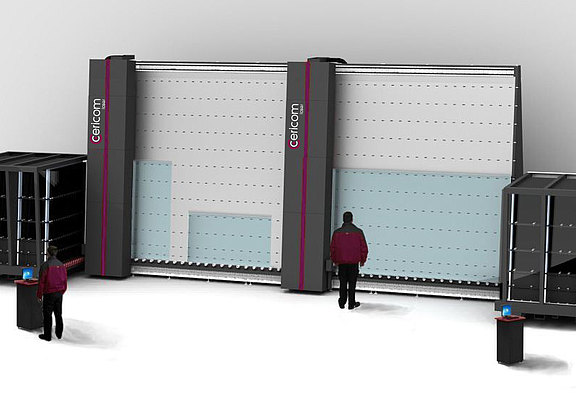

The c-vertica series is our latest patented innovation and a true space saver. Wherever horizontal alignment of the glass is not required, this system provides you with a powerful laser machine for glass processing.

As the glass panels do not have to be laid horizontally anymore, they can easily be placed on the machine, which makes the whole handling process a lot easier. This means that even door-sized glass formats can be set up on the c-vertica by a single employee.

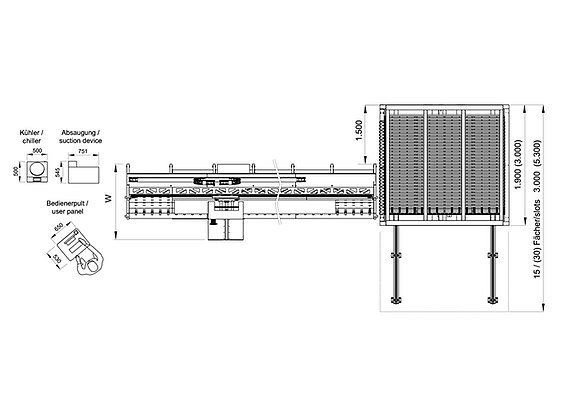

The glass panels stand on the machine with a 6° inclination and thanks to the use of soft rollers or support elements they are well protected from scratches and other potential damages.

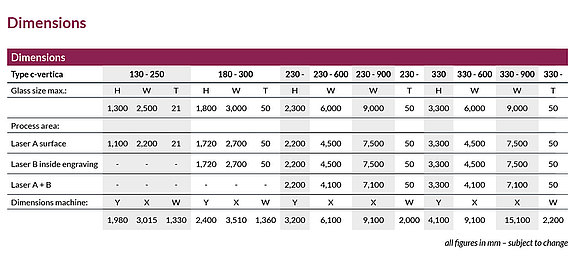

We manufacture the c-vertica systems in various sizes and expansion stages. Upon request, we will gladly send you a non-binding offer with technical data and prices.

Laser anti-slip: transparency and high resistance

The anti-slip laser structuring creates small indentations on all glass surfaces that can be walked on (even with a post-treatment on toughened safety glass). They create a suction effect that prevents slipping when wet, making it a safer option for public areas.

Unlike printed structures, which disappear after a few months, cericom's slip resistance leaves 90% of the glass surface untouched and develops its effect through vacuum. The small depressions are not subject to any significant abrasion and the surface remains easy to clean. The Wismar Materials Testing Institute has certified the slip-resistant glass surfaces produced with cericom laser machines with "R9" and "R10".