For decoating

Clear coatings are removed with pulsed infrared lasers, matt coatings are removed with CO2 lasers. In addition, we offer other lasers as an alternative in order to achieve the best quality and productivity - depending on the type of coating. Depending on the laser process, coatings such as lacquers, mirror coatings, not yet tempered enamel, LowE coatings or even conductive coatings can be removed and structured in a targeted manner and with the highest resolution. The process developed by cericom for targeted laser ablation enables flexible and economical decoating or structuring of glass for changing designs and both large and small quantities.

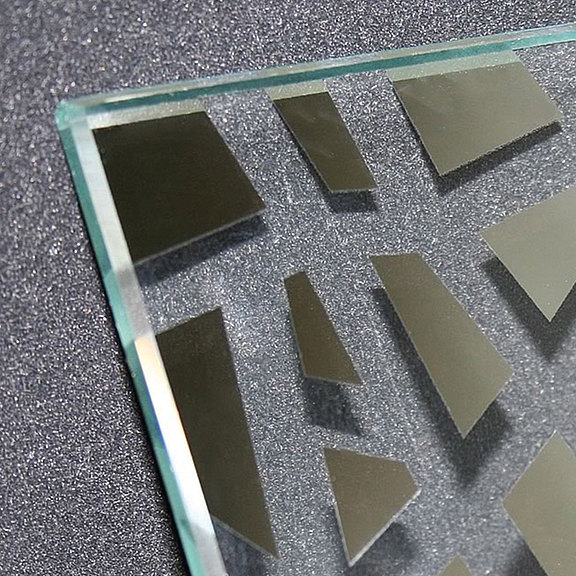

Laser ablation can achieve significantly higher resolutions and contour sharpness than screen or digital printing. Sampling can also be carried out quickly and efficiently using laser decoating, as no intermediate steps are required. The glass exposed under the coating usually remains undamaged without any matting of the glass surface.