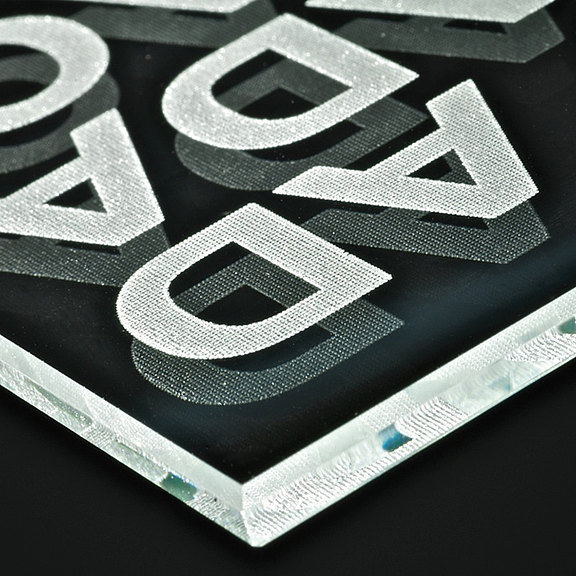

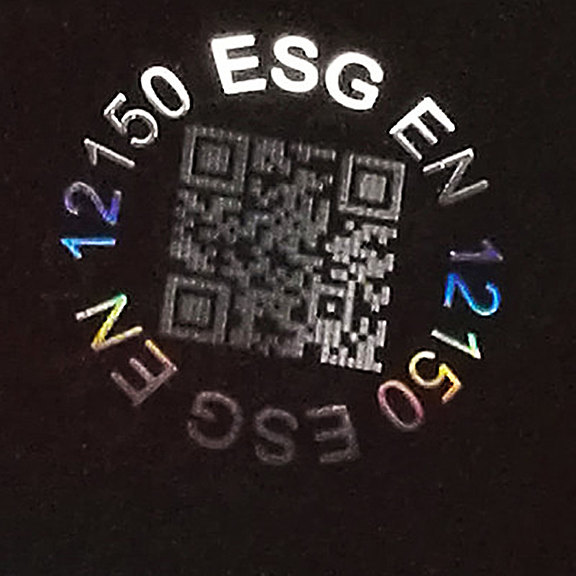

For marking, matting, surface engraving

For this application, mainly CO2 lasers are used on cericom machines. With this type of laser, you can process the surfaces of all flat glass products available on the market without restriction and structure many coatings.

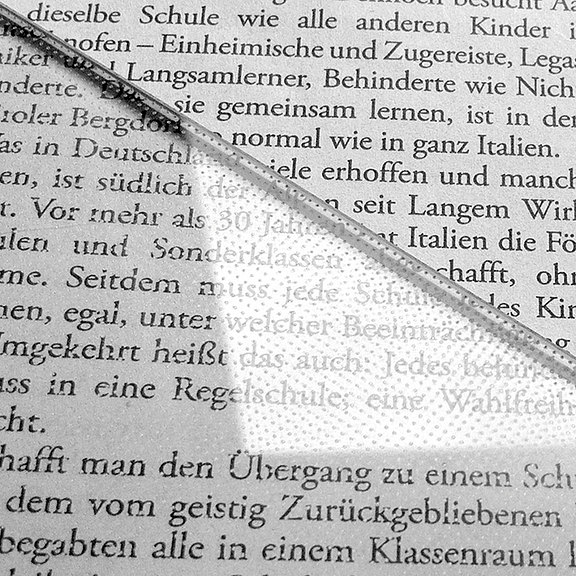

The glass surface is frosted by the CO2 laser beam via a small amount of material removal and additional melting of the glass surface. Advantage: Laser-matted glass surfaces are less sensitive to fingerprints and dirt than glass surfaces that are roughened by sandblasting or etching.

In addition, the glass marking can also be used specifically to create slip-resistant glass surfaces. For this purpose, however, no additional material is applied to the surface, but only micropores are created with the laser beam that are subject to almost no wear.