c-mark consists of a module with laser and 2D-scanner and a lens, optionally available with variable focal lengths. A particular adapter plate enables simple and flexible integration of the lasermarking module into the existing system technology and facilitates maintenance and replacement. The rotatable laser scan head enables variable exit of the laser beam, so that processing can also be carried out can also be carried out simply “overhead”, for example.

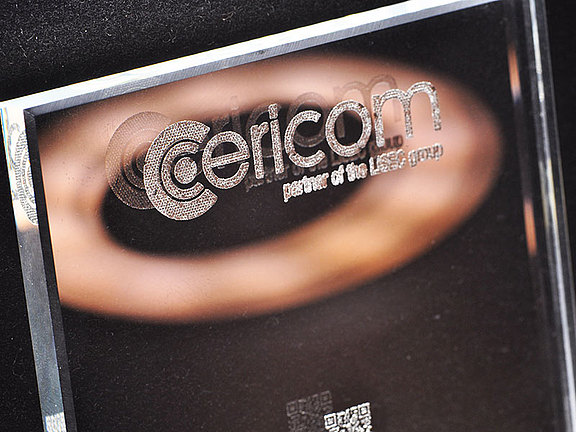

It can be used wherever high quality markings are required or copyright is an issue for example, in the marking of safety glass, in the automotive industry, in medical technology or for jewelry and perfumes. c-mark enables easy integration into existing plants and machines and is also available as an alternative “stand-alone solution”.

Advantages

- Modular, compact and powerful laser etching/scribing and marking

- High marking quality and durability

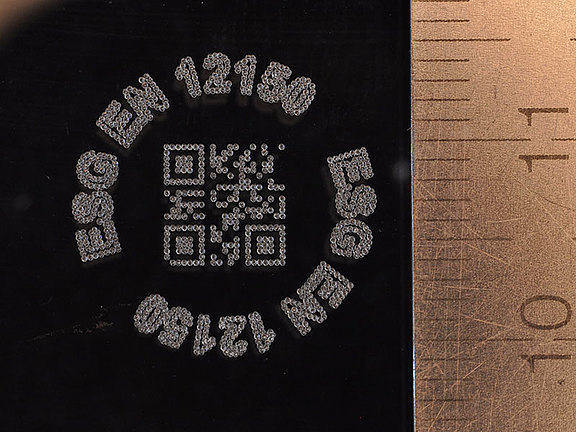

- Marking directly on the glass

- No weakening of the glass in the marked area

- Easy service

- Electronic readout

- Individual product code for referencing

- Marking often takes less than one second

- For permanent traceability of any kind of visible and almost invisible markings, as graphics, unlimited lines of text in any orientation, bar codes, 2D datamatrix or QR-codes

- Professional software with simple user interface

- Low power consumption

- Marking of additional materials possible

- Specifically developed for markings on any kind of glass, even tempered glass

- For low and high speed production lines, optionally with “marking on the fly”-technology

- Environmentally friendly and highly cost-effective, no use of any consumables necessary!

- Simple operation, manual (via operating software or foot switch) or automated (via production control system)

- Easy and safe installation and maintenance in production lines or as stand-alone; small and adjustable scan head for more flexibility, easy exchange of laser system based on adjustable mounting plate with preadjusted laser position.

- Use of high-quality laser components in a robust casing ensures maximum service life, proofed in harsh environment installations

c-mark consists of:

- Marking module with laser, 2D galvanometer scanner, and focusing lens

- Adapter plate for easy service and trouble-free replacement (Plug&Play)

- Control cabinet

- Application-specific software

- Variable lens focal lengths enable different working distances and marking qualities

- Cable connections suitable for drag chains ensure robust control of the laser marking module and secure data transfer

- Small footprint allows easy and flexible integration, even in automated production lines

High flexibility

- Available as a stand-alone marking solution (single workstation in glass processing)

- Integrable into automated production lines (mechanical and electronic interfaces)

- TCP/IP interface enables external control

Additional reading unit (camera-based code recognition)

- For electronic capture of 1D/2D barcodes and

- Interface for data transfer

- Electronic data processing

Special added values through

- Cloud-based database solution (e.g., Global Unique Identifier Generation)

- Dynamic connection with ERP systems

- Linkage with relevant machine data in production (IoT or Industry 4.0)

- life cycle management of glass